4 Methods for Proper Labeling of Chemical Products in Cabinets

Proper labeling of chemical products in cabinets is crucial for ensuring laboratory safety, preventing accidents, and complying with current regulations. Good labeling facilitates the immediate identification of substances and associated risks, minimizing errors and hazards.

In this article, we will explore four effective methods for labeling chemical products.

-

Use of Standardized Labels

An essential method for labeling chemical products is the use of standardized labels that comply with international regulations such as the Globally Harmonized System of Classification and Labeling of Chemicals (GHS).

Within the GHS system, chemical substances are classified based on the risks they pose to human health and the environment. These are divided into four main groups:

- Physical hazard classes – including explosives, oxidizing gases, flammable liquids, self-reactive substances, and substances or mixtures corrosive to metals.

- Health hazard classes – including acute toxicity, skin corrosion, respiratory sensitization, carcinogenicity, or mutagenic effects on reproductive cells.

- Environmental hazard classes – including hazards to the aquatic environment.

- Additional EU hazard class – including hazards to the ozone layer.

Major countries worldwide, including Australia, Brazil, Canada, China, Japan, South Korea, the United States, and the European Union, have adopted the GHS, which will push other nations to implement the system in the near future. While GHS is a global standard established by the United Nations, its implementation timeline and methods are determined at the national level.

Every GHS-compliant label must include six key elements:

- Signal words – such as "Danger" or "Warning" to specify the risk level.

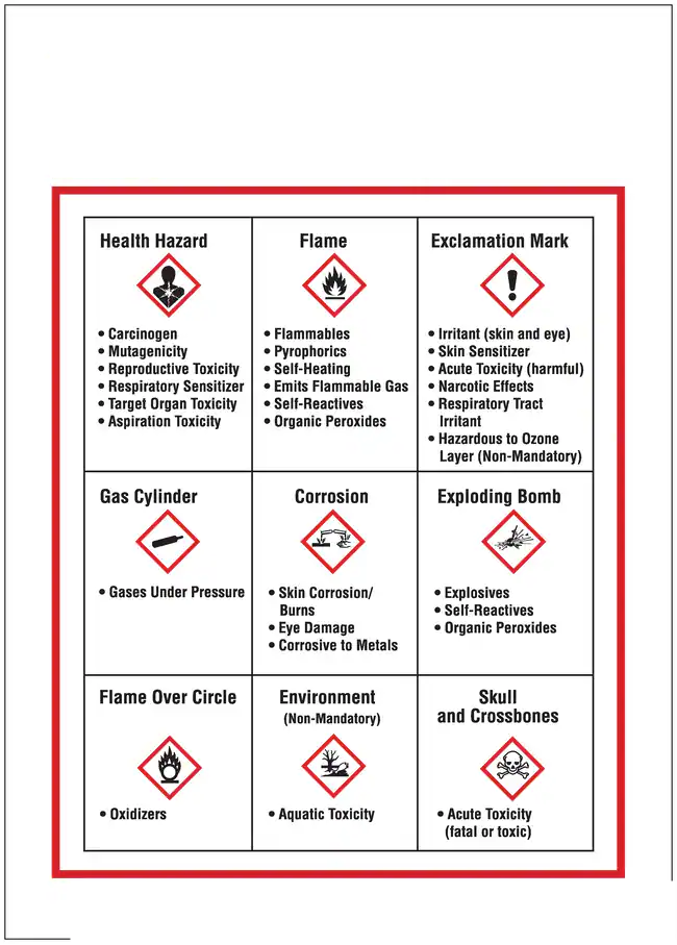

- Pictograms – also known as GHS hazard symbols, indicating health, chemical, physical, or environmental hazards.

- Manufacturer information – including the name, address, and telephone number of the manufacturer.

- Precautionary statements – outlining prevention, response, storage, and disposal requirements when handling hazardous chemicals.

- Hazard statements – describing the specific danger level of the chemical substance.

- Product identification – indicating the name of the chemical substance or product.

-

Color Coding

Color coding is an effective visual method for quickly differentiating various types of chemical substances stored in cabinets. For example, specific colors can be used to identify acids, bases, flammable substances, and toxic chemicals. This approach not only enhances safety but also facilitates cabinet organization.

-

Chemical-Resistant Labels

It is essential to use chemical-resistant labels to ensure that information remains readable over time. Labels should withstand exposure to corrosive substances, high temperatures, and humidity.

Labels made from synthetic materials such as polypropylene, polyester, polyolefin, and polyamide offer excellent performance against aggressive chemicals and solvents.

These labels are resistant to acids and bases, making them ideal for identifying containers used to store highly corrosive reagents in organic chemistry and forensic laboratories, analytical research facilities, environmental/agricultural labs, and public utility services that regularly test water quality.

Acid-resistant labels must be able to withstand prolonged exposure and immersion in concentrated sulfuric acid (H₂SO₄), nitric acid (HNO₃), hydrochloric acid (HCl), hydrofluoric acid (HF), trichloroacetic acid (TCA), and sodium hydroxide (NaOH). They are perfect for use in clinical and research facilities handling corrosive acids and alkalis.

-

Updating and Maintaining Labels

Labeling chemical products is not a one-time process. It is important to regularly update labels to reflect any changes in stored substances or regulatory requirements. Periodic checks of label integrity are essential for maintaining a safe environment.

Finally, here are three key guidelines from the INAIL document “Hazardous Chemical Agents: Instructions for Workers”, offering simple recommendations for anyone working in a laboratory or handling chemical agents:

- Always read the label before using a chemical product. Ignoring it means overlooking potential risks.

- Do not transfer substances into containers other than the original ones. If necessary, thoroughly clean the new container, remove any old labels, and properly relabel it.

- Ensure that all hazardous materials are correctly labeled. If you are unsure about a container’s contents, avoid using it and notify your supervisor.